Cylindrical roller bearings are indispensable components in various mechanical systems, offering high radial load capacity and robust performance in demanding applications. However, a recurring question engineers and designers face is: Are cylindrical roller bearings suitable for vertical shafts? To address this, one must delve deeper into the design intent, load distribution, lubrication behavior, and installation nuances of these bearings when mounted vertically.

This article explores the suitability of cylindrical roller bearings for vertical shaft applications, analyzing their performance limits, engineering considerations, and common concerns. We will also include practical FAQs and a tabular comparison with other bearing types to enhance clarity and application accuracy.

Understanding Cylindrical Roller Bearings

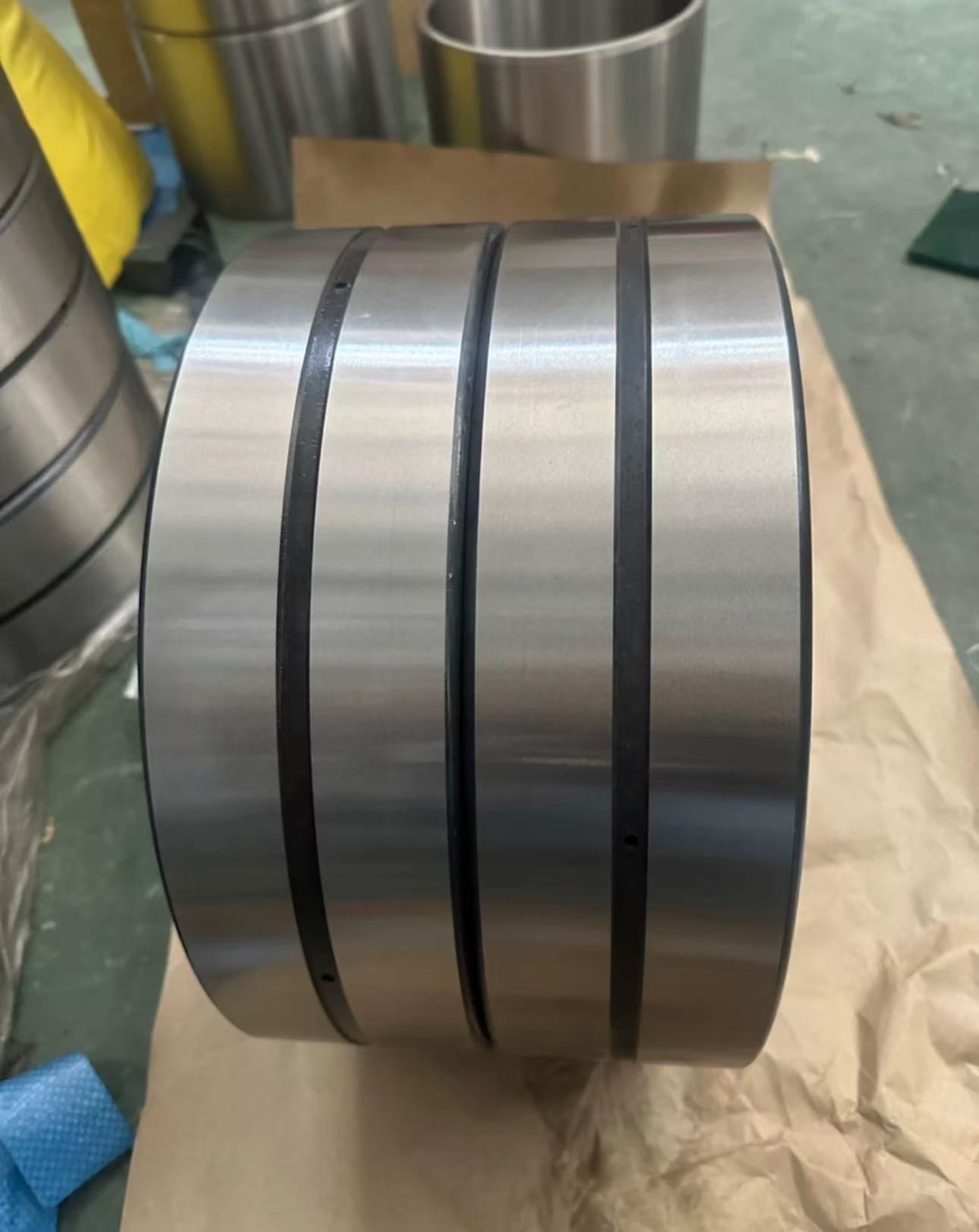

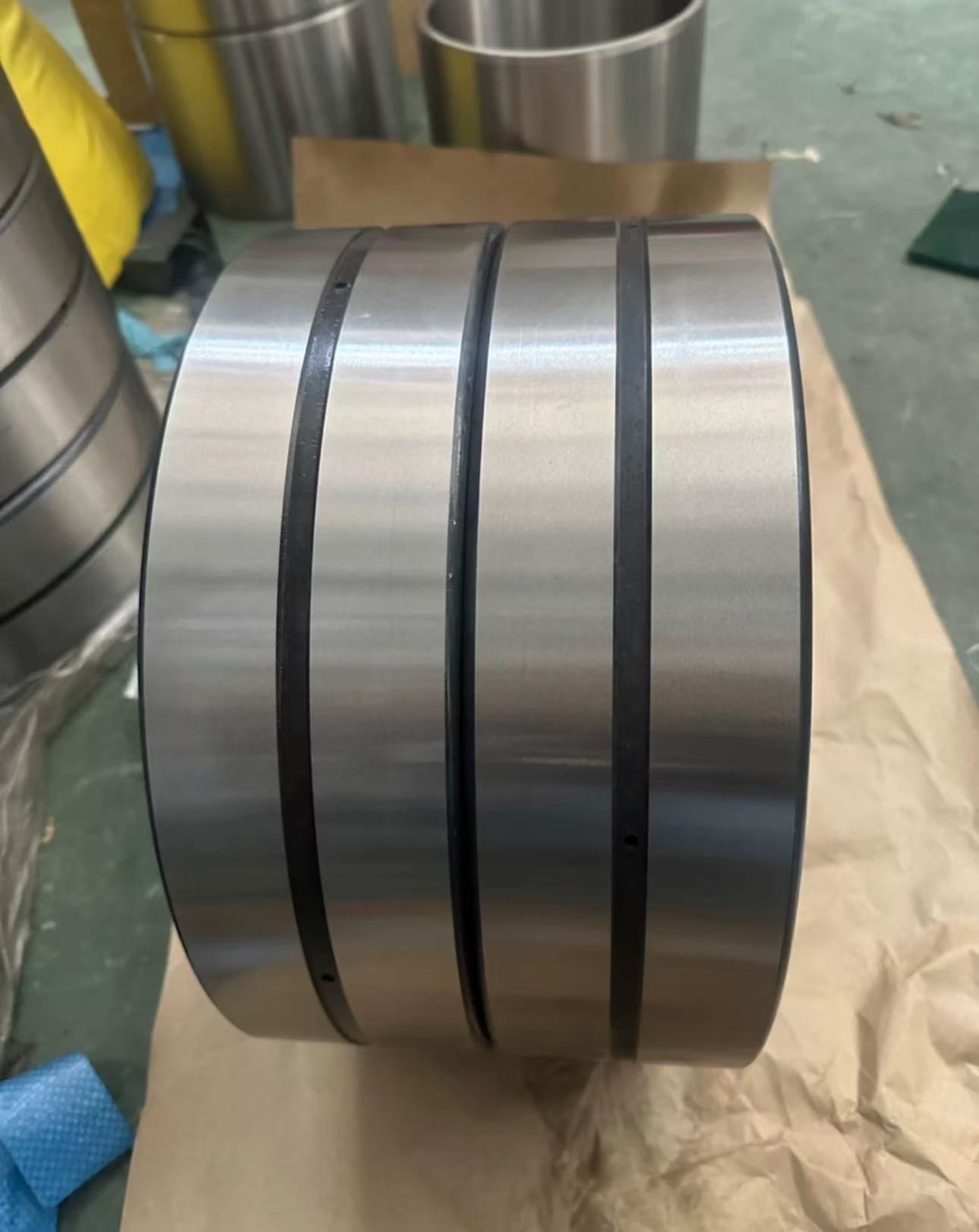

Cylindrical roller bearings are a subtype of rolling-element bearings. As the name suggests, they use cylinders (as opposed to balls or tapered elements) to carry the load. These rollers make contact along a line rather than a point, allowing them to withstand heavier radial loads than ball bearings. Structurally, they consist of an inner ring, an outer ring, and cylindrical rolling elements separated by cages to reduce friction and maintain spacing.

These bearings come in several configurations such as single-row, double-row, and full-complement types. Some include flanges on the inner or outer rings to accommodate limited axial load or prevent axial movement.

When installed on horizontal shafts, cylindrical roller bearings operate exceptionally well due to optimal radial load alignment and straightforward oil retention. However, the scenario changes when you rotate the axis by 90 degrees—installing them on a vertical shaft.

Vertical Shaft Application – Key Challenges

Axial Load Handling

The primary challenge in using cylindrical roller bearings on a vertical shaft is their limited ability to handle axial (thrust) loads. Since these bearings are predominantly designed for radial loading, mounting them vertically places gravitational forces and load-induced axial components in a direction they aren’t optimized for.

Unless the bearing has integrated flanges or is combined with thrust bearings, it can experience early wear, misalignment, or even axial displacement. In full-complement versions without cages, axial friction can further accelerate degradation.

Lubrication Complexity

Gravity significantly affects lubrication behavior in vertical orientations. In horizontal setups, grease or oil can naturally remain within the bearing cavity. However, in vertical shafts, especially with open or semi-open designs, lubricants may flow downward due to gravity, leading to starvation at the top contact surfaces.

To combat this, engineers often employ:

Vertical lubrication channels

Oil bath systems with circulation pumps

High-viscosity greases

Still, these solutions increase system complexity and maintenance requirements.

Engineering Modifications for Vertical Use

To adapt cylindrical roller bearings for vertical shafts, certain modifications and precautions are often necessary:

Use of Locating Flanges

Some cylindrical roller bearings come with flanges on both the inner and outer rings. These flanges help manage axial displacement and ensure the rollers stay in place under vertical gravity stress. This configuration is particularly important when the vertical shaft supports rotating machinery with uneven load distribution.

Combined Bearing Assemblies

In high-load vertical applications, cylindrical roller bearings are often used in combination with thrust bearings. For example, a cylindrical roller bearing handles radial loads, while a thrust bearing absorbs axial loads from the vertical orientation. This dual-bearing strategy prevents premature failure and ensures prolonged service life.

Preload and Mounting Accuracy

Mounting precision is even more critical in vertical shafts. Improper preload can lead to increased vibration and uneven load distribution. Engineers often use precision shims, wave springs, or axial clamps to control internal clearance and ensure optimal contact geometry.

Performance Summary Table

Below is a comparative table summarizing the characteristics of cylindrical roller bearings versus alternative bearings in vertical shaft applications:

| Feature | Cylindrical Roller Bearing | Tapered Roller Bearing | Angular Contact Ball Bearing |

| Radial Load Capacity | Very High | High | Moderate |

| Axial Load Capacity | Low (unless flanged) | High | High |

| Suitable for Vertical Shafts | Conditionally | Yes | Yes |

| Lubrication Retention (Vertical) | Moderate to Low | High | High |

| Ideal Use | Radial load-intensive | Combined load | High-speed axial applications |

This table shows that cylindrical roller bearings can be used vertically, but only with design adjustments or when axial loads are minimal or well-managed.

Frequently Asked Questions (FAQ)

Can cylindrical roller bearings work in a vertical gearbox?

Yes, but only if the design compensates for axial loads. The bearing should be flange-supported or paired with a thrust bearing. Also, attention must be given to oil retention and circulation to avoid upper-section lubrication failure.

Do I need special cages for vertical shafts?

In vertical applications, caged cylindrical roller bearings are preferable over full-complement types. The cages reduce internal friction and allow better lubricant flow, which is crucial when gravity pulls the lubricant away from critical areas.

How can I prevent lubricant loss?

Use grease with thickeners, labyrinth seals, or recirculating oil systems. Also, consider vertically-oriented channels and deflectors that maintain even lubrication across all contact surfaces.

What’s the lifespan difference?

Cylindrical roller bearings on a horizontal shaft typically last longer due to optimal load distribution. On a vertical shaft, life expectancy can drop by 20–40% if not engineered properly for axial and lubrication challenges.

Conclusion

So, are cylindrical roller bearings suitable for vertical shafts?

Yes—but with conditions. They can perform well when:

Axial loads are minimal or externally managed.

Bearings are equipped with flanges or paired with thrust bearings.

Lubrication systems are optimized for vertical operation.

If any of these factors are overlooked, performance and lifespan can be compromised. Therefore, while cylindrical roller bearings are not the first-choice for vertical shafts, they are not excluded from such applications either. With thoughtful engineering and system-level adaptations, they can offer reliable and long-term performance in vertical orientations.